1 Engine Components:

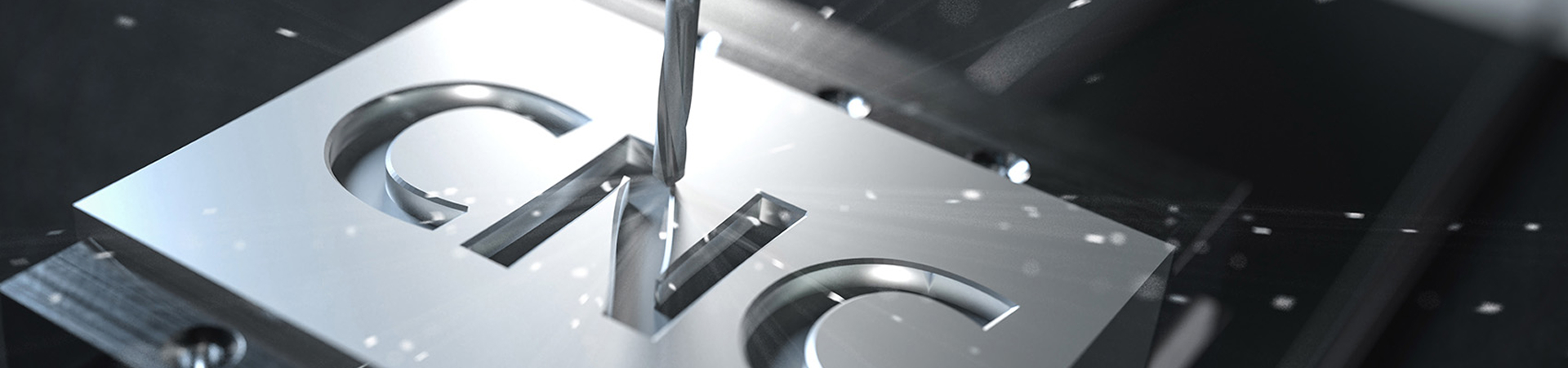

CNC machining is crucial for producing precise engine components such as cylinder heads, engine blocks, pistons, and crankshafts. These parts require high accuracy to ensure proper engine performance, durability, and efficiency. CNC machining allows for tight tolerances and high surface finish quality, essential for engine parts that withstand extreme conditions.

2 Transmission Parts:

Parts such as gears, shafts, and housings that make up a vehicle’s transmission system are often manufactured using CNC machining. The precision provided by CNC allows for the creation of gears with specific tooth profiles and smooth surfaces, ensuring optimal transmission performance and longevity.