3 Electric Vehicles (EVs)

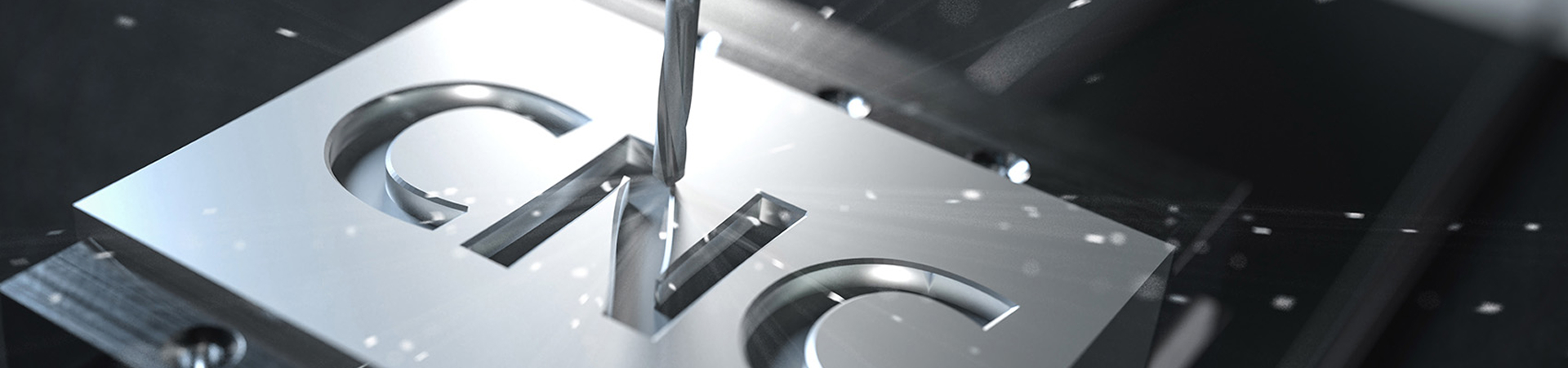

Electric vehicles rely heavily on CNC machining for the production of key components that enhance performance, safety, and energy efficiency. CNC machining is used for parts such as battery enclosures, electric motors, power electronics, and chassis components.

1) Battery Enclosures: CNC machining is used to manufacture battery cases that are durable, lightweight, and capable of protecting lithium-ion cells from external damage.

2) Motor Housings and Components: CNC machines create parts for electric motors, ensuring precision in the motor housing, rotor, and stator.

3) Power Electronics: High-precision parts are required for components like inverters and converters that control the flow of electricity between the battery, motor, and other systems within the vehicle.

4 Hydrogen Energy

Hydrogen energy technologies, such as fuel cells and hydrogen storage systems, also require highly specialized components that can be made using CNC machining.

1) Fuel Cells: CNC-machined parts are used in fuel cell stacks, where precision is needed for components like plates, gaskets, and manifolds that handle the fuel cell's chemical reactions.

2) Hydrogen Storage Tanks: CNC machining is used to manufacture the tanks that store hydrogen under high pressure. These parts must be strong, leak-proof, and lightweight, requiring high levels of accuracy.

5 Geothermal Energy

Geothermal power plants, which harness energy from the Earth’s heat, also utilize CNC machining for various parts. These include pumps, valves, and turbines that must be built to withstand extreme temperatures and pressures.

1) Turbine Parts: CNC machining is used to produce turbine blades and housings that can operate efficiently in the high-temperature environments of geothermal plants.

2) Pumps and Valves: CNC machines are used to manufacture pumps and valves for controlling the flow of geothermal fluids, ensuring precision and reliability under challenging conditions.

6 Battery and Energy Storage Systems

CNC machining plays a key role in the production of parts for energy storage systems, such as lithium-ion batteries and grid-scale storage solutions. Precision parts are essential to ensure the safe and efficient operation of these systems.

1) Battery Casings: CNC machining ensures that battery casings are precisely made to fit the cells and protect them from external damage while maintaining electrical conductivity.

2) Heat Management Components: In energy storage systems, heat management is critical. CNC-machined components, such as heat exchangers and cooling plates, help regulate the temperature of battery systems to maximize performance and safety.

7 Smart Grids and Energy Distribution

CNC machining is used to produce components for smart grids and energy distribution systems. These parts must meet high-quality standards for electrical conductivity, durability, and functionality.

1) Connectors and Switches: CNC machining is used to create connectors and switches that are essential in energy distribution and smart grid technologies. These parts must be manufactured with precision to ensure smooth operation and safety.

2) Control Panels and Enclosures: CNC-machined enclosures protect the electronic components and control systems that manage the distribution of electricity within smart grids.

In summary, CNC machining plays a pivotal role in the new energy industry by providing high-quality, durable, and precise components for technologies that are driving the global transition to sustainable energy solutions. Whether it's wind, solar, electric vehicles, hydrogen, or other renewable energy systems, CNC-machined parts are integral to their efficiency and success.

Are you operating in this industry? Feel free to get a quote now !