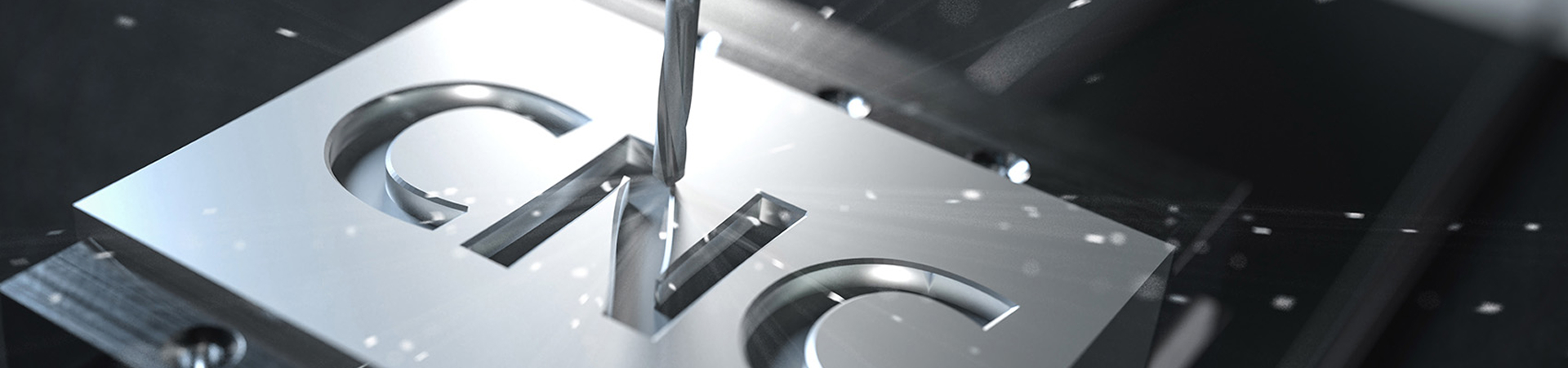

CNC (Computer Numerical Control) machining is a highly precise manufacturing process widely used in the medical industry to produce components with tight tolerances and complex geometries. Here’s a detailed look at how CNC machining is applied in the medical field:

Applications of CNC Machining parts in Medical industry

1 High Precision and Accuracy

CNC machines offer high precision, which is crucial in the medical industry where small tolerances are required for safety and performance. Medical parts, such as implants, surgical instruments, and prosthetics, need to be manufactured with exact measurements to ensure they fit and function properly in the human body. CNC machining can produce parts with tolerances as tight as ±0.001 inches, making it ideal for such applications.

2 Types of Medical Parts Manufactured by CNC

1) Orthopedic Implants: Parts like hip joints, knee replacements, and dental implants are made using CNC machining. These components often need to be made from biocompatible materials such as titanium, stainless steel, and specialized polymers.

2) Surgical Instruments: CNC machining is used to manufacture a wide variety of surgical tools, including scalpels, forceps, and scissors. These tools must be extremely sharp, durable, and resistant to wear, which is achievable with CNC machining.

3) Prosthetics: Custom prosthetics, such as limbs and hearing aids, are often made with CNC machines. The machines allow for the precise creation of custom shapes and sizes that match the unique anatomy of patients.

4) Medical Devices: CNC machining is also used to produce parts for various medical devices, including pacemakers, infusion pumps, and diagnostic machines. These parts require high reliability and accuracy to function properly in critical medical applications.

3 Material Choices

CNC machining supports a wide range of materials that are essential in the medical field. These include:

1) Titanium: Known for its strength, corrosion resistance, and biocompatibility, titanium is commonly used in orthopedic implants and surgical tools.

2) Stainless Steel: This material is often used for surgical instruments and medical device components due to its strength, durability, and resistance to infection.

3) Polymers and Plastics: Biocompatible plastics such as PEEK (Polyetheretherketone) are used for non-load-bearing implants and devices like hearing aids.

4) Aluminum: Lightweight and corrosion-resistant, aluminum is used for some medical devices and instruments.

4 Customizability

CNC machining allows for the creation of custom parts tailored to individual patient needs. For instance, personalized implants or prosthetics can be produced using 3D scanning technology combined with CNC machining, which helps create models that precisely fit a patient's anatomy.

In summary, CNC machining plays a pivotal role in the medical industry by enabling the production of high-precision, reliable, and customizable parts. Its applications range from implants and prosthetics to surgical instruments and medical devices. The process's ability to handle complex geometries, use a wide variety of biocompatible materials, and maintain consistency makes it indispensable in ensuring patient safety and improving medical outcomes.

Are you operating in this industry? Feel free to get a quote now !