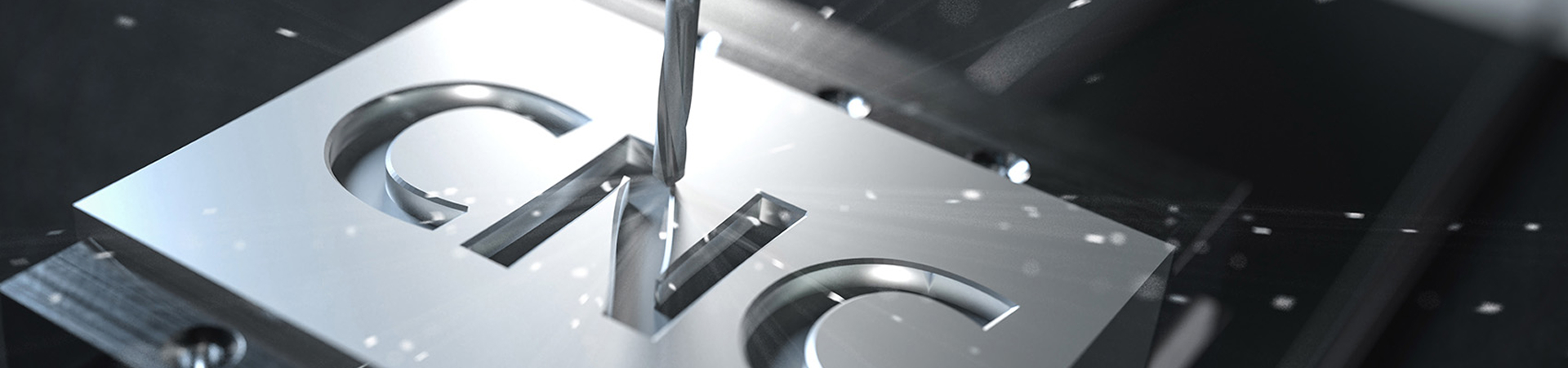

5 High Efficiency and Speed:

CNC machines can operate continuously, producing parts in a high-volume and time-efficient manner. This high-speed production is essential for the robotics industry, where the demand for rapid prototyping and mass production of parts is high.

6 Prototyping and Testing:

Before mass-producing components, robotic companies often use CNC machining for prototyping. This allows for the rapid development of prototypes, which can be tested and refined. CNC machining provides the flexibility to quickly iterate on design changes, ensuring that parts meet functional and design requirements.

7 Consistency and Repeatability:

Once a design is finalized, CNC machining ensures consistent production of parts with the same specifications every time. This repeatability is vital for robotics, where multiple identical parts are often needed, such as for robot arms or legs, sensors, and joints.

8 Advanced Robotic Components:

CNC machining is used to create some of the most critical components in advanced robotic systems, including:

1) Robot arms and joints: Machining ensures that these parts have the precision necessary for smooth and controlled movement.

2) End effectors (grippers and tools): The grippers or tools used by robots to perform tasks are often CNC-machined to meet the specific needs of the operation.

3) Actuators: CNC machining allows the production of complex actuator components, which are responsible for driving movement in robots.

4) Sensor housings: CNC machining ensures that sensor housings are precise and durable, providing protection to the sensors used in robotics.

9 Cost-Effectiveness for Low-Volume Production:

While traditional manufacturing methods may require expensive molds or tooling, CNC machining can be more cost-effective for low-volume production runs, making it ideal for the robotics industry, where the need for custom parts or smaller production quantities is often higher.

10 Automation and Integration:

CNC machines themselves can be integrated into automated systems, allowing for fully automated production lines for robotics components. This integration supports the development of highly efficient manufacturing processes for the robotics industry.

In summary, CNC machining plays a critical role in the robotics industry by enabling the production of high-precision, customized, and complex parts required for robotic systems. With its ability to handle various materials, produce intricate geometries, and maintain consistency, CNC machining is essential for meeting the demands of the fast-evolving robotics sector.

Are you operating in this industry? Feel free to get a quote now !