Bending is a key metal forming process used to shape sheet metal, plates, or profiles into angled or curved components. Different bending methods are applied based on material, precision, and production needs:

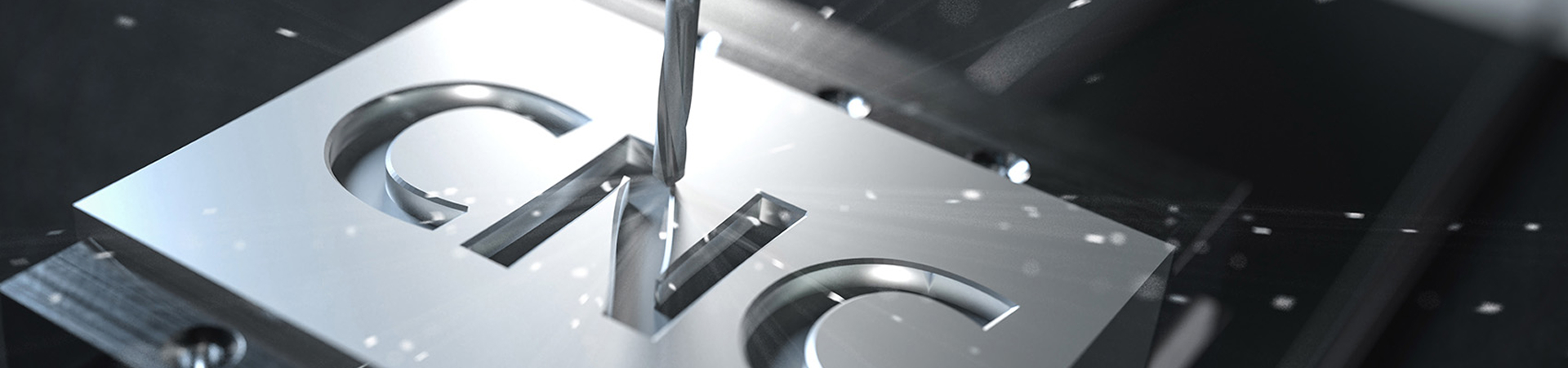

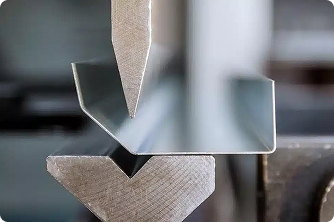

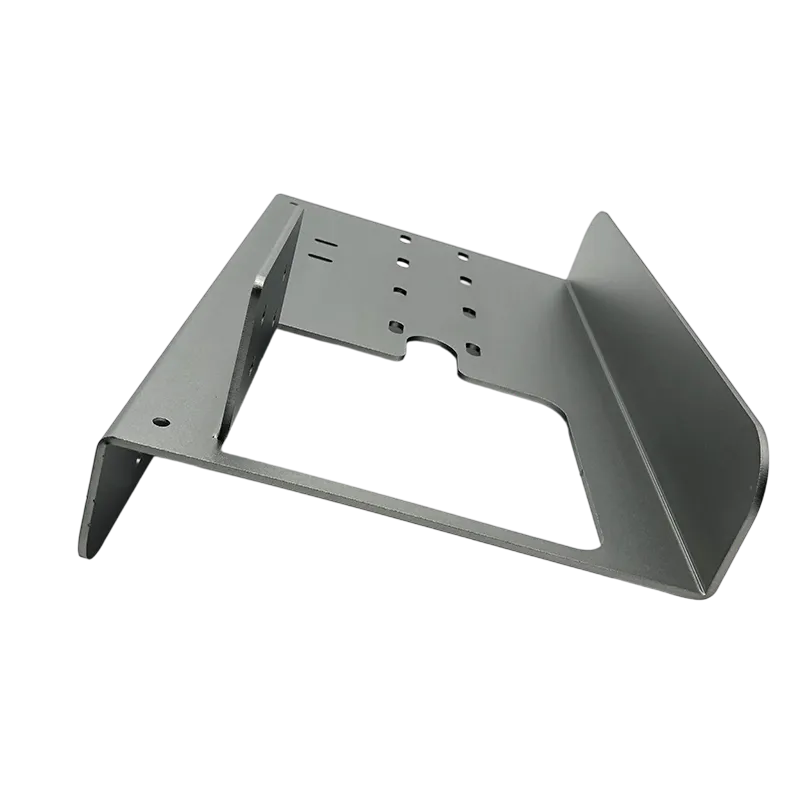

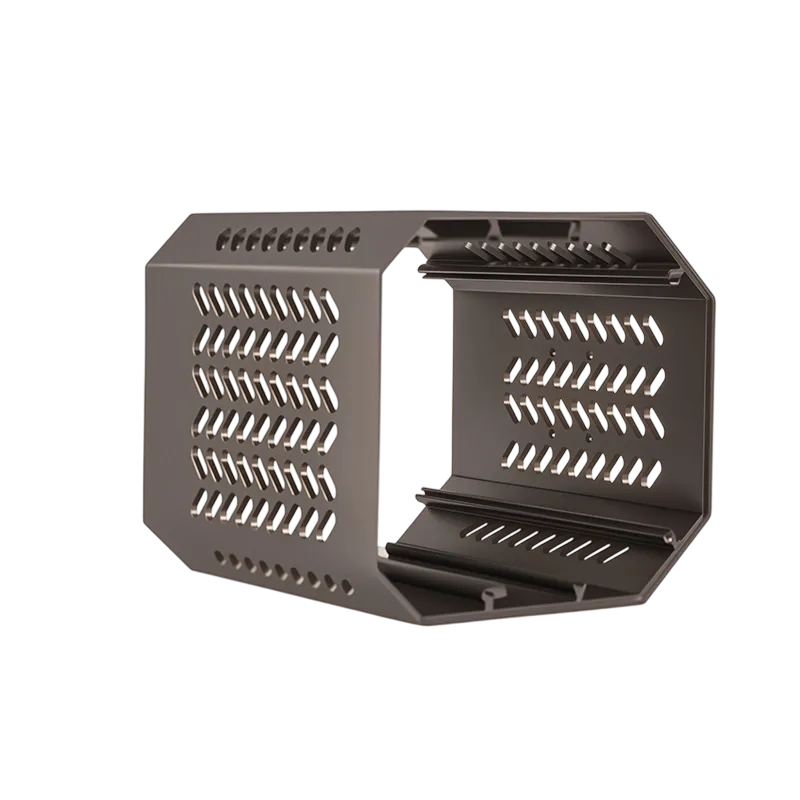

CNC Bending (Most Common)

Uses computer-controlled machines for precise, repeatable bends.

Ideal for complex shapes, high accuracy, and large production volumes.

Applications: automotive parts, industrial enclosures, electronic housings.

Manual Bending (Traditional Method)

Performed by skilled operators with hand tools or simple machinery.

Best for small batches or custom one-off parts.

Limitations: lower precision and slower than automated processes.

Roll Bending (Rolling)

Gradually forms curves or cylinders by passing metal through rollers.

Suitable for large radius bends, pipes, and structural components.

Applications: storage tanks, pipe bends, architectural structures.

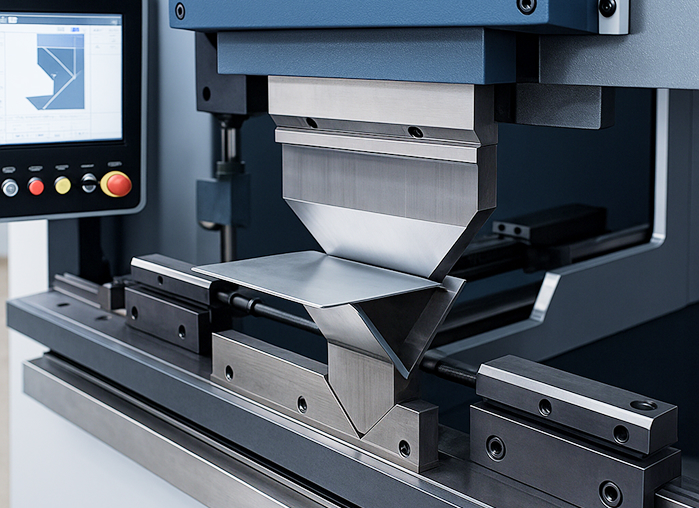

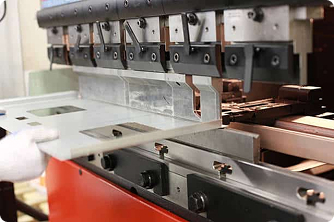

Press Bending (Stamping)

Uses a press machine and dies to bend metal sheets at specific angles.

Fast and consistent, perfect for high-volume production.

Applications: brackets, panels, metal enclosures.

Flanging (Edge Bending)

Bends sheet edges to strengthen parts or assist assembly.

Increases rigidity without extra material, allows interlocking designs.

Applications: automotive panels, cabinets, electronic housings.