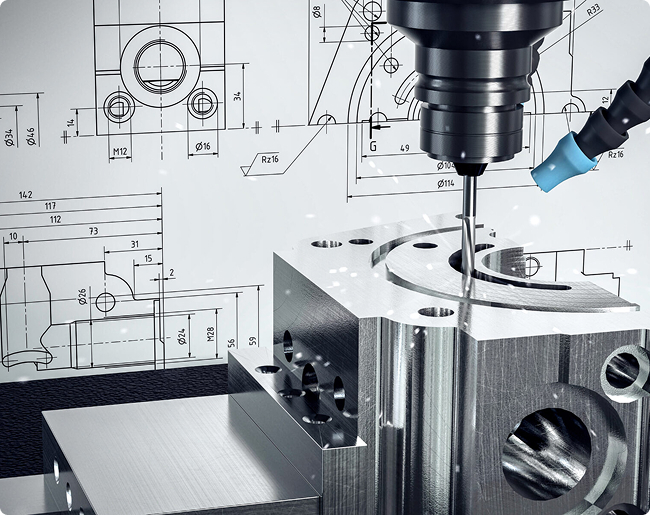

Drawings: Including the part's detailed dimensions, shape, and tolerance requirements.The drawing should be in 3D like STP,STEP,IGS format, or 2D like DWG,DXF,PDF format.

Materials and surface treatment: Specify the metal or plastic material to be machined, and specify the requirement of the surface treatment.

Quantity: Confirm the batch production quantity.

Delivery Time: Clearly define the required delivery time.