From design to finished product, Jixing Aluminum provides you with one-stop precision machining solutions!

We would always like to provide the professional technology, highest quality, low price, fastest lead time…

E-mail: lilyfang@jxalu.cn

Tel.: +86 158 4014 9884

Custom made CNC Machining Services

Own factory, online video visit factory

8 project engineers with 20 years experience

Tolerances contorl to ± 0.01mm

9 quality inspection equipment control

Simple components: 3 days prototype machining delivery.Complex components : 7 days prototype machining delivery.

MOQ 1 pcs

CNC Machining parts

Inquire NowCNC machining parts are precision components manufactured using computer numerical control technology, commonly used in industries such as aerospace, automotive, and medical and so on. Key features include high accuracy, repeatability, and the ability to machine complex shapes. Compared to traditional methods, CNC machining offers higher production efficiency and reduced error rates. It is capable of working with various materials like all kinds of metals and plastics, making it suitable for both batch production and custom orders. The precise control system ensures each part meets strict quality standards.

CNC Machining Parts Tolerance

We offer advanced CNC machining services that deliver high‑quality precision components from prototype to full‑scale production. With a well‑equipped in‑house facility and experienced engineering team, we ensure reliable and repeatable manufacturing outcomes tailored to your specific design and functional requirements.

During the production process, we will implement the stricter standards than ISO Tolerances DIN ISO 2768-1 for the unrequired parts, and below are the CNC machining components standard tolerances of our machines.

| Nominal linear range tolerance(mm) | Linear dimensions DIN ISO 2768-F | Our CNC machining metal parts | Our plastic parts |

0.5 up to 3 over 3 up to 6 over 6 up to 30 over 30 up to 120 over 120 up to 400 | ±.0.05 ±.0.05 ±0.1 ±0.15 ±0.2 | ±.0.02 ±.0.03 ±0.05 ±0.05 ±0.1 | ±0.05 ±0.05 ±0.1 ±0.15 ±0.2 |

| Nominal angle range tolerance(mm) | Linear dimensions DIN ISO 2768-F | Our CNC machining metal parts | Our plastic parts |

≤10 10~50 50~120 120~400 | ±1° ±0°30′ ±0°20 ±0°10 | ±1° ±0°30' ±0°20 ±0°10 | ±1° ±0°30′ ±0°20 ±0°10 |

Strict Quality Control & Tight Tolerances

Our CNC machining processes maintain stringent dimensional accuracy and repeatability to meet demanding engineering standards. Tolerance control is strictly enforced throughout production to ensure fit and performance.

Flexible Production Range

We cater to one‑off prototypes as well as batch manufacturing, offering fast turnaround for simple parts and scalable solutions for complex assemblies.

Wide Material Compatibility

We machine a comprehensive range of materials including aluminum alloys, stainless steel, carbon steel, brass, copper, and industrial‑grade plastics — enabling optimal material selection for your application.

Surface Finishing & Secondary Options

Our surface processing options include anodizing, sandblasting, polishing, powder coating, electroplating, laser marking, and more — enhancing durability, appearance, and functional properties.

CNC Machining parts Materials

Here below are some commonly used processing materials, Apart from the materials listed below, if you have any special material requirements, as long as they are available on the market then we can also provide.

Aluminum

Al6061, AI6063, Al6082, AI7075, Al2024, Al5052, ADC12, A380, A384, A413, YL113 etc.

Stainless Steel

201, 202, 301, 303, 304, 304L, 316, 316L, 321, 310S, 401, 409, 410, 420J1, 420J2, 430, 439, 443, 444, G90 etc.

Steel

Mild Steel, Carbon Steel, 4140, 4340, Q235, Q34513, 20#, 45#, etc.

Iron

20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc.

Brass

C35600, C36000, C37700, C37000, C37100, C28000, C26000, C24000, C22000, etc.

Copper

C11000, C12000, C12200, C10100, etc.

Plastic

POM, Peek, PMMA, ABS, Del Rin, Nylon, PVC, PP, PC, etc.

CNC Machining parts Surface treatment

| Name | Description | Suitable Material | Color | Texture |

As machined |

Has a As-machined surface roughness of 3.2μm (126 μin), which removes sharp edges and deburs parts cleanly.

|

All metal

|

Mill finished

|

Satin

|

Sand blasting |

A method that uses high-pressure gas or water to spray sand or other fine granular materials onto the surface of a metal machined product, in order to remove dirt or increase the surface roughness.

|

Aluminum, Stainless steel, Steel, Brass, copper

|

Mill finished

|

Matte

|

Anodized |

Anodizing is an electrochemical process, mainly used to form a protective oxide film on the surface of metals (especially aluminum and its alloys). It can effectively prevent metal oxidation and corrosion, enhance wear resistance, and offer a variety of color options to improve aesthetics.

|

Aluminum

|

Silver, black, red, blue, green, yellow, grey, purple, gold, champagne

|

Smooth, matte

|

Alodine |

The Alodine coating is formed on the surface of metals through a chemical reaction, creating a protective oxide film. This film can isolate the metal from air and moisture, thereby enhancing its corrosion resistance.

|

Aluminum

|

Silver, gold

|

Smooth, matte, glossy

|

Powder Coating |

The surface of the powder-coated products is smooth and flat, with uniform color. It has extremely strong acid resistance, alkali resistance, impact resistance and wear resistance. It can withstand strong ultraviolet radiation and acid rain for a long time without any phenomena such as coating powdering, fading or peeling. Typical thickness ranging from 50 μm up to 150μm.

|

All metal

|

Any color as required

|

Glossy

|

Polishing |

Polishing is the process of modifying the surface of a workpiece using flexible polishing tools and abrasive particles or other polishing equipment, with the aim of achieving a smooth surface or mirror-like luster. The surface roughness can generally reach Ra 0.8~Ra 0.1.

|

All metal

|

Mill finished

|

Smooth, Glossy

|

Electroplating |

Electroplating is a process that uses electrolysis to attach a metal film to the surface of metal parts, thereby preventing metal oxidation, improving wear resistance, conductivity, reflectivity, corrosion resistance and enhancing appearance.

|

Aluminum, steel, Stainless steel

|

Glod, Silver, black, red, blue, colorful

|

Smooth, Glossy

|

Wire drawing |

The wire drawing process involves grinding the product to form lines on the surface of the workpiece, which can reflect the texture of the metal material and achieve a decorative effect.

|

Aluminum, steel, Stainless steel, ABS, brass

|

Glod, Silver, black, grey, bronze, champagne

|

Satin

|

Knurling |

Rolling the handle on metal products or on other working surfaces involves the mechanical process of pressing patterns onto the surface through rolling. It is mainly used for anti-slip purposes.

|

All metal

|

Same as product

|

Matte

|

Painting |

Spray the coating evenly on the surface of the product, then make it to dry and harden, forming a hard coating film. It has the functions of protection, aesthetics and marking.

|

All metal

|

Any color as required

|

Glossy, semi-glossy, highlight, Matte

|

Laser marking |

A marking method that uses a high-energy-density laser to irradiate the surface of product, causing the vaporization of the surface material or a chemical reaction resulting in color change, thereby leaving a permanent mark. It can produce various characters, symbols, and patterns, and the size of the characters can range from millimeters to micrometers, which has special significance for product anti-counterfeiting.

|

All metal

|

As customer required

|

N/A

|

Screen printing |

Screen printing is manufactured through photochemical or mechanical processing. By squeezing the ink and passing it through the screen plate, it is deposited on the surface of the substrate, therefore obtaining a large-area patterned film.

|

Aluminum, steel, Stainless steel,brass

|

As customer required

|

N/A

|

Passivation |

Passivation reactions are widely applied in various industrial fields, such as chemical engineering, aviation, and automobiles. In these fields, passivation reactions can enhance the corrosion resistance, toughness and durability of metals, thereby extending their service life.

|

Aluminum, steel, Stainless steel, brass

|

Gold, Silver, grey, black

|

Smooth, Glossy

|

Processing Capability

Multiple processing methods to meet your needs: CNC machining, CNC milling, CNC turning, 5 axis CNC machining, Stamping, Laser cutting, Bending, Welding...

QC Inspection Tools

The quality control team at Jixing make sure that no compromises are made and only best quality products are leaving the factory, Together with the customer individual quality control standards are developed and strictly followed for each product.

Cmms

CMM detection equipment is an instrument that calculates the coordinates (x, y, z) of each point on the workpiece and various functional measurements through data processors or computers. It can accurately measure dimensions, positioning accuracy, geometric accuracy, and contour accuracy, etc.

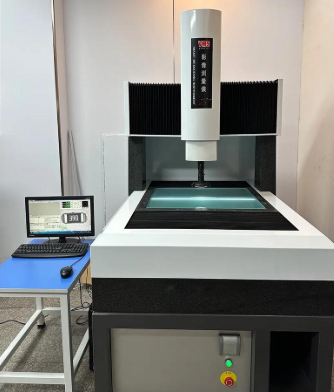

2.5 Dimensional Coordinate Machine

2.5 Dimensional coordinate machine is a sophisticated measuring device that is an upgraded version of the 2D imaging instrument. It achieves three-dimensional geometric parameter measurement by installing probes, and can accurately measure angles, diameters, radii, the distance from a point to a line, the eccentricity of two circles, and the distance between two points, etc.

Hardness Tester

The hardness machine is a device used for measuring the hardness of metal materials. It is mainly applied to the surface hardness testing of materials such as Aluminum, steel, alloys, and electroplated coatings.

Height Gauge

1. Arbitrary zero point setting; 2. Two reference origin settings (two coordinate systems); 3. Metric/American unit conversion; 4. Probe compensation; 5. Measuring the distance between two points; 6. Measuring the center of a circle / Measuring the straight angle; 7. Measuring the inner diameter/outer diameter and difference of the center distance; 8. Motor-driven digital dial to detect angle.

Vernier Caliper

Vernier caliper can be used to measure the inner diameter, outer diameter, length, width, thickness, depth and pitch of the parts. It has a wide range of applications and belongs to universal measuring tools.

Feeler

Feeler is made of thin steel sheets and consists of several gauge pieces (rulers) of different thicknesses in a set. It is mainly used to measure the gap between two mating surfaces.

Roughness Tester

Roughness tester is widely used for the inspection of processing surfaces Roughness of various metals and non-metals.

Thread Gauge

The thread gauge is a tool used for measuring the dimensions of internal and outernal threads.

Micrometer Caliper

Micrometer caliper is a more precise tool for measuring length than a vernier caliper. Using it to measure length can achieve an accuracy of 0.01mm.

Related Applications

Frequently Asked Questions

From design to finished product, Jixing Aluminum provides you with one-stop precision machining solutions!

We would always like to provide the professional technology, highest quality, low price, fastest lead time…