From design to finished product, Jixing Aluminum provides you with one-stop precision machining solutions!

We would always like to provide the professional technology, highest quality, low price, fastest lead time…

E-mail: lilyfang@jxalu.cn

Tel.: +86 158 4014 9884

Custom Made CNC Turning Services

Own factory, online video visit factory

6 project engineers with 20 years experience

Tolerances contorl to ± 0.01mm

9 quality inspection equipment control

Simple components 3 days prototype machining delivery.

Complex components : 7 days prototype machining delivery.

MOQ 1 pcs

CNC Turning Parts

Inquire NowCNC turning parts are precision components manufactured using Computer Numerical Control (CNC) turning technology. In CNC turning, the workpiece is rotated at high speed while a cutting tool moves along one or more axes to remove material and create the desired shape. This process is widely used to produce cylindrical or symmetrical parts with high dimensional accuracy and a smooth surface finish.

CNC Turning Parts Tolerance

As an ISO 9001-certified factory, we are dedicated to meeting stringent tolerance standards with precision CNC turning parts. Based on your design specifications, our CNC lathe processes can achieve accuracy down to ±0.005 inches. For metal milling, we adhere to ISO 2768-m tolerance standards, while plastic machining follows ISO 2768-c standards—ensuring each product aligns with your exact requirements.

| Part Size Limits | Metal | Plastic | No Drawings |

| Minimum part size | ±400mm | ±400mm | ISO 2768 Medium |

| ±15.7in | ±15.7in | ||

| Minimum part size | ±1.0mm | ±1.0mm | ISO 2768 Medium |

| ±0.03in | ±0.03in | ||

| Maximum Part Aperture | ±400mm | ±400mm | ISO 2768 Medium |

| ±15.7in | ±15.7in | ||

| Maximum Part Aperture | ±0.3mm | ±0.3mm | ISO 2768 Medium |

| ±0.01in | ±0.01in | ||

| Maximum part length | ±600mm | ±600mm | ISO 2768 Medium |

| ±23.6in | ±23.6in | ||

| Maximum part length | ±0.1mm | ±0.1mm | ISO 2768 Medium |

| ±0.003in | ±0.003in | ||

| Wall thickness | ±0.5mm | ±0.5mm | ISO 2768 Medium |

| ±0.01in | ±0.01in | ||

| Angle | 0.1° | 0.1° | ISO 2768 Medium |

| Tolerance | ±5μm | ±0.01mm | ISO 2768 Medium |

We offer professional CNC turning services that deliver high‑quality precision components with one‑on‑one engineering support, capable of handling simple prototypes as well as complex production parts with tight tolerances.

Our processes support precision control to ±0.01 mm (±5 μm), ensuring that each part aligns with your design requirements. Stringent quality inspection tools such as CMMs, micrometers, and roughness testers are used to guarantee consistent performance.

We machine a wide range of materials, including:

● Metals: aluminum alloys, stainless steels, carbon steels, brass, copper

● Plastics: POM, Nylon, PC, ABS, etc.

This versatility lets you choose the optimal material for strength, conductivity, weight, and finish.

In addition to turning, we offer multiple finishes such as as‑machined, anodized, powder coated, and satin. These options improve corrosion resistance, visual appeal, and functional performance of parts.

We support low minimum order quantities (MOQ 1 piece) and rapid prototype delivery:

● Simple parts: approx. 3 days

● Complex parts: approx. 7 days

This flexibility is ideal for prototyping, iterative design, or small‑batch production.

Our capabilities extend beyond turning to include CNC milling, 5‑axis machining, stamping, bending, laser cutting, and welding — offering you a full range of precision manufacturing services in one place.

● High accuracy & consistency — CNC turning achieves fine features and repeatable results for demanding applications.

● Fast turnaround — efficient production that shortens your time to market.

● Custom flexibility — ideal for OEM/ODM production with tailored specifications.

CNC Turning Parts Materials

Here below are some commonly used processing materials, Apart from the materials listed below, if you have any special material requirements, as long as they are available on the market then we can also provide.

Aluminum

Al6061, AI6063, Al6082, AI7075, Al2024, Al5052, ADC12, A380, A384, A413, YL113 etc.

Stainless Steel

201, 202, 301, 303, 304, 304L, 316, 316L, 321, 310S, 401, 409, 410, 420J1, 420J2, 430, 439, 443, 444, G90 etc.

Steel

Mild Steel, Carbon Steel, 4140, 4340, Q235, Q34513, 20#, 45#, etc.

Iron

20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc.

Brass

C35600, C36000, C37700, C37000, C37100, C28000, C26000, C24000, C22000, etc.

Copper

C11000,C12000,C12200,C10100,etc.

Plastic

POM, Peek, PMMA, ABS, Del Rin, Nylon, PVC, PP, PC, etc.

CNC Turning Parts Surface treatment

| Name | Description | Suitable Material | Color | Texture |

As machined |

Has a As-machined surface roughness of 3.2μm (126 μin), which removes sharp edges and deburs parts cleanly.

|

All metal

|

Mill finished

|

Satin

|

As machined |

Has a As-machined surface roughness of 3.2μm (126 μin), which removes sharp edges and deburs parts cleanly.

|

All metal

|

Mill finished

|

Satin

|

As machined |

Has a As-machined surface roughness of 3.2μm (126 μin), which removes sharp edges and deburs parts cleanly.

|

All metal

|

Mill finished

|

Satin

|

Processing Capability

Multiple processing methods to meet your needs: CNC machining, CNC milling, CNC turning, 5 axis CNC machining, Stamping, Laser cutting, Bending, Welding...

QC Inspection Tools

Jixing Aluminum is dedicated to enhancing custom made manufacturing capabilities, including CNC turning, rapid prototyping, and mold manufacturing, along with corresponding quality control processes. We adhere to ISO 9001:2015 standards. Using advanced manufacturing technology and strict quality control with state-of-the-art inspection equipment, we ensure high quality, precision, and durability for CNC turning parts.

Below are our strict QC inspection tools

Cmms

CMM detection equipment is an instrument that calculates the coordinates (x, y, z) of each point on the workpiece and various functional measurements through data processors or computers. It can accurately measure dimensions, positioning accuracy, geometric accuracy, and contour accuracy, etc.

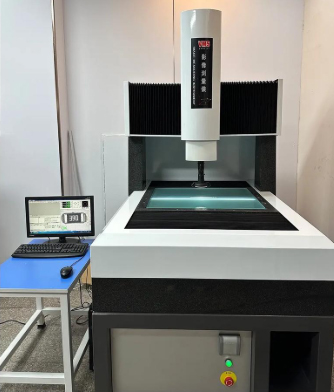

2.5 Dimensional Coordinate Machine

2.5 Dimensional coordinate machine is a sophisticated measuring device that is an upgraded version of the 2D imaging instrument. It achieves three-dimensional geometric parameter measurement by installing probes, and can accurately measure angles, diameters, radii, the distance from a point to a line, the eccentricity of two circles, and the distance between two points, etc.

Hardness Tester

The hardness machine is a device used for measuring the hardness of metal materials. It is mainly applied to the surface hardness testing of materials such as Aluminum, steel, alloys, and electroplated coatings.

Height Gauge

1. Arbitrary zero point setting; 2. Two reference origin settings (two coordinate systems); 3. Metric/American unit conversion; 4. Probe compensation; 5. Measuring the distance between two points; 6. Measuring the center of a circle / Measuring the straight angle; 7. Measuring the inner diameter/outer diameter and difference of the center distance; 8. Motor-driven digital dial to detect angle.

Vernier Caliper

Vernier caliper can be used to measure the inner diameter, outer diameter, length, width, thickness, depth and pitch of the parts. It has a wide range of applications and belongs to universal measuring tools.

Feeler

Feeler is made of thin steel sheets and consists of several gauge pieces (rulers) of different thicknesses in a set. It is mainly used to measure the gap between two mating surfaces.

Roughness Tester

Roughness tester is widely used for the inspection of processing surfaces Roughness of various metals and non-metals.

Thread Gauge

The thread gauge is a tool used for measuring the dimensions of internal and outernal threads.

Micrometer Caliper

Micrometer caliper is a more precise tool for measuring length than a vernier caliper. Using it to measure length can achieve an accuracy of 0.01mm.

Related Applications

Frequently Asked Questions

From design to finished product, Jixing Aluminum provides you with one-stop precision machining solutions!

We would always like to provide the professional technology, highest quality, low price, fastest lead time…