From design to finished product, Jixing Aluminum provides you with one-stop precision machining solutions!

We would always like to provide the professional technology, highest quality, low price, fastest lead time…

E-mail: lilyfang@jxalu.cn

Tel.: +86 158 4014 9884

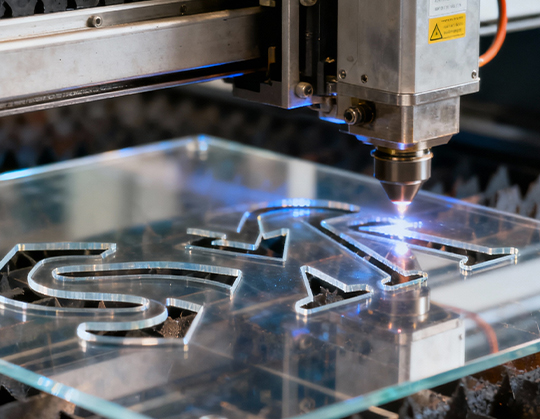

Laser metal cutting service

Laser cutting is an advanced manufacturing process that uses a high-powered laser beam to cut, engrave, or shape materials with exceptional precision and speed. The technology is widely used across industries such as automotive, aerospace, electronics, medical devices, construction, and consumer products due to its ability to produce complex geometries, smooth edges, and highly accurate parts without the need for additional finishing.

Key Features

High Precision

Versatile Materials

Minimal Material Waste

Non-Contact Process

Flexibility

Advantages Of Laser Cutting

Faster turnaround time compared to traditional machining methods.

High repeatability and consistency for mass production.

Clean edges with minimal post-processing required.

Cost-effective for complex and customized designs.

Laser Cutting Technical Specifications

| Parameter | Specification | ||||

| Laser Type | CO₂ Laser (non-metals, thin metals) | ||||

| Fiber Laser (high efficiency metals) | |||||

| YAG Laser (precision) | |||||

| Laser Power Range | 500–1000W (thin sheets) | ||||

| 1000–3000W (medium sheets) | |||||

| 4000–12000W+ (thick plates) | |||||

| Typical Material Thickness | Carbon Steel: ≤ 50 mm | ||||

| Stainless Steel: ≤ 40 mm | |||||

| Aluminum Alloy: ≤ 30 mm | |||||

| Brass & Copper: ≤ 10–15 mm | |||||

| Cutting Speed | Example: 1000W laser cutting 1 mm carbon steel → 6–10 m/min | ||||

| Repeat Positioning Accuracy | ±0.02–0.05 mm (high-precision models: ±0.01 mm) | ||||

| Cutting Area | Standard sizes: 1500 × 3000 mm, 2000 × 4000 mm | ||||

| Custom sizes available: up to 2500 × 6000 mm or larger | |||||

| Minimum Kerf Width | 0.1–0.2 mm | ||||

| Gas Types | Oxygen (O₂) Higher speed but oxidized edges | ||||

| Nitrogen (N₂) Clean cut, no oxidation | |||||

Application Fields

Laser metal cutting Material

Here below are some commonly used processing materials, Apart from the materials listed below, if you have any special material requirements, as long as they are available on the market then we can also provide.

Metal Materials

The common metal materials includes steel, stainless steel, aluminum, brass,copper alloy and etc. Thickness for different metal materials, includes mild steel: less than 40mm, stainless steel: less than 20mm, aluminum: less than 20mm, brass and copper alloy: less than 10mm...

Plastic Materials

As a professional manufacturer of laser cutting in China, we offer a variety of sizes plastic materials for your application, including rubber, acrylic, ABS, PC, PP, PVC, PE (LDPE/HDPE), PU, PVDF, PTFE, PET, PA6, PA66, MC, PEl, UPE, and etc. There is usually no limit to the plastic sheet thickness...

Wood Materials

We specialize in custom wood laser cutting services and offer a variety of shapes and sizes of laser-cut wood parts with plywood, MDF, birch, cherry, maple, bamboo, and more. They are widely used in wooden toys, Christmas decorations, home decorative, office decorative, wood inlays, souvenirs, gifts, crafts, and artistic products...

From design to finished product, Jixing Aluminum provides you with one-stop precision machining solutions!

We would always like to provide the professional technology, highest quality, low price, fastest lead time…